Precision Fabrication

Precision Fabrication

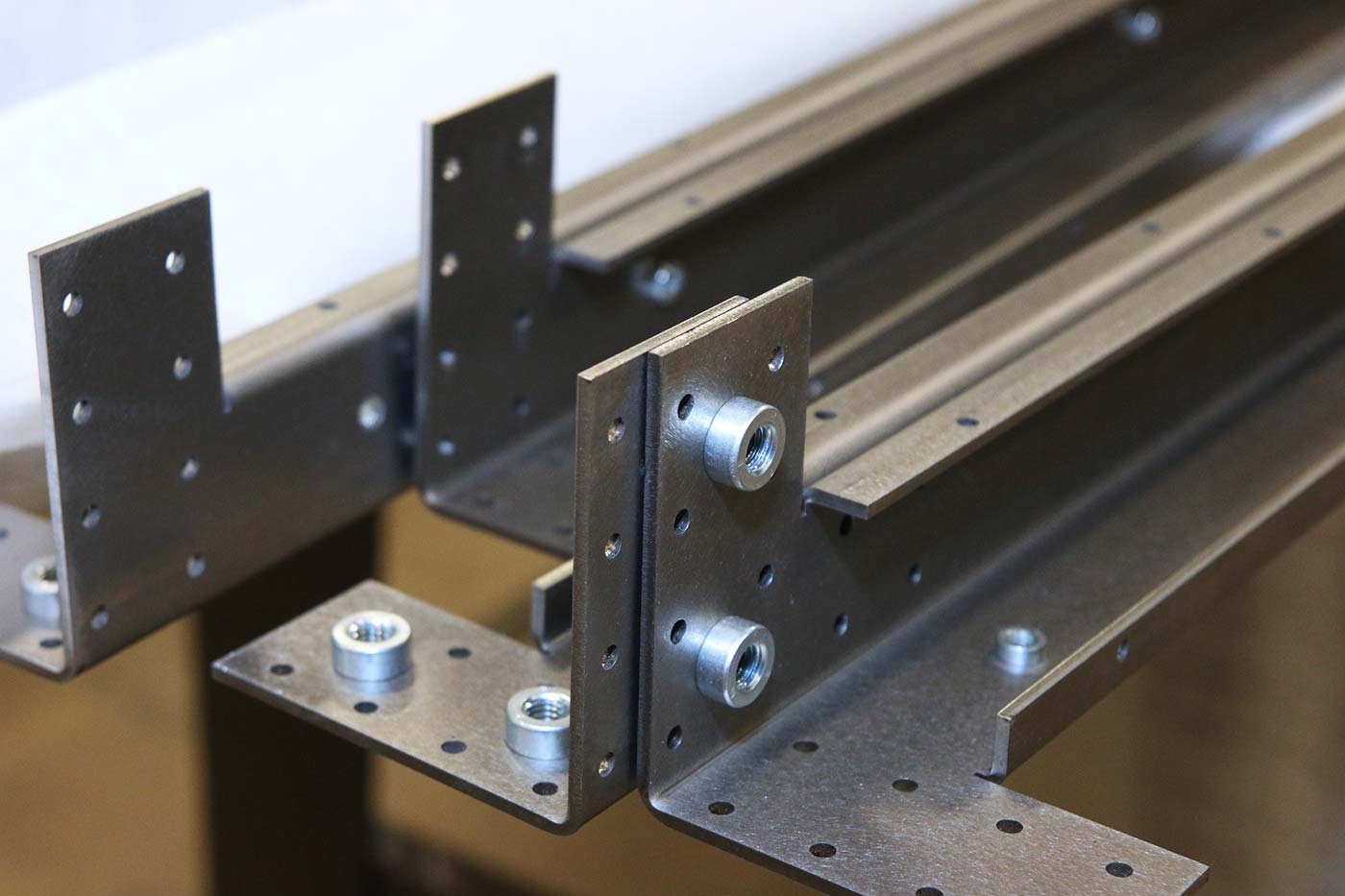

What do you get when you combine a highly skilled staff with top of the line equipment? You get Mid Valley Metals' precision fabrication services for industry. We are the leader in precision fabrication. Mid Valley Metals focuses on high-end precision parts for medical testing equipment and automation, 3D printers, electronic testing equipment and industrial processing automation. We specialize in challenging projects, and the most precise specifications.

Large manufacturers come to Mid Valley Metals because they know that they can count on us to provide top-level service and products with a quick turnaround. In addition to quality forming, welding and precise cutting services, we also provide finishing services like zinc plating, anodizing, electro-polishing, stainless steel polish, powder coating, and mirror finish polishing. We work with a wide variety of customers that require flawless, cosmetically grained and polished stainless steel products. Silk-screening, laser etching and label making services are also available to put the finishing touch on your parts.

Mid Valley Metals has developed a streamlined process to make sure that we can meet all of your precision manufacturing needs FAST. Our highly skilled staff is cross-trained to allow for maximum flexibility, keeping a laser sharp focus on your project from beginning to end. Our top of the line machinery can handle large, complex jobs quickly, making Mid Valley an industry leader in speed and quality.

CASE STUDIES

Less Waste. Big Savings.

CHALLENGE: To improve material utilization and throughput for the laser work center.

APPLICATION: Utilize improvements in software to nest multiple shapes in a common material.

RESULTS: Through multi-shape nesting of parts with a common material thickness, we are able to maximize the amount of parts that can be put on a sheet. This results in a savings to the customer in increased material efficiency and reduced waste.

Software Provides Quality.

CHALLENGE: Reduce the potential for insertion of wrong sized Pem hardware or missing hardware.

APPLICATION: Use InsertLogic programming software from Haegar to program part hardware profile and generate a visual program for the operator to follow.

RESULTS: Pem operators face a great challenge in being able to determine the correct pem hardware, its location, and its orientation while trying to keep cycle times to a minimum.

Mid Valley Metals recently invested in InsertLogic software that will keep track of the quantity and variety of pems for each part, as well as provide visual aids to operators to show where and how to insert each pem. By giving the operators more information and tools to keep track of each part, variability is being reduced while maintaining low cycle times and improved quality.

TESTIMONIALS

"I have been using Mid Valley Metals for about 7 years now. They produce quality work and products for our store displays. Mid Valley has excellent customer service and are always willing to do whatever it takes to get the job done."

- James

"The parts I order have a very tight tolerance and I was struggling to find someone to make them for me. After trying many different fabrication shops around town I thankfully found Mid Valley Metals. No one can beat their quality or precision. I would recommend using Mid Valley Metals for any of your business’ sheet metal needs."

- Michael